Cosmetic Bottle Filling Capping And Sleeve Labeling Machine

·Rotary Automatic Cosmetic Bottle Filling Capping Machine

·Automatic Shrink Sleeve Applicator Machine

-Description

This production line has functions of filling low-viscosity liquid, feeding inner plugs and bottle caps, tightening caps, putting on sleeve labels and shrinking labels automatically. Production speed can reach 1800 bottles/h. Equipped with stainless steel magnetic pump, it has high filling accuracy, which suits for filling eye drops, perfume, lavender oil. We can customize this cosmetic bottle filling capping and sleeve labeling machine to meet your production requirements. It would be better if you can send your samples of products to us for testing the machines.

Hot Tags: cosmetic bottle filling capping and sleeve labeling machine, China cosmetic bottle filling capping and sleeve labeling machine manufacturers, suppliers, factory, olive oil filling machine, paste filling line, edible oil bottle filling machine, cooking oil filling machine, flour packing machine, shampoo filling line

>Filling Capping Machine

|

Machine Model |

ZS-AFC14 |

|

Voltage |

220V/110V 50-60Hz |

|

Power |

1.5kW |

|

Filling Pump |

316 Stainless Steel Magnetic Pump |

|

Working Speed |

About 30 bottles/min(depending on bottle size and filling materials) |

|

Max Flow Rate |

4L/min*2(based on water) |

|

Suitable Bottle Size |

Can be customized |

|

Suitable Bottle Cap Size |

Can be customized |

|

Air Pressure |

0.4-0.6MPa |

|

Machine Size |

About 2040*820*1430mm |

|

Package Size |

About 2140*1600*890mm |

|

Package Weight |

About 381.5kg |

>Sleeve Labeling Machine

|

Machine model |

ZS-STB150 |

|

Bottle diameter range |

φ28mm-φ125mm (can be customized) |

|

Bottle height |

30mm ~ 280mm (can be customized) |

|

Label length |

30mm~250mm (can be customized) |

|

Label thickness |

0.03 mm~0.13 mm (PVC, PET, OPS, materials are all available) |

|

Sleeve standard error |

±1.5mm |

|

Paper tube inner diameter |

5"~10" (can be adjusted) |

|

Machine speed |

150 bottles/min (based on label length) |

|

Voltage |

220V Single Phase |

|

Power |

1.5KW |

|

Conveyor belt |

standard 2M |

|

Machine size |

About 2950*1030*1870 mm |

|

Machine weight |

About 464Kg |

|

Package size |

About 2250*1250*2140 mm |

|

Package weight |

About 493Kg |

>Shrink Machine

|

Tunnel length |

About 1800mm |

|

Tunnel width |

About 395mm |

|

Tunnel height |

About 360mm |

|

Suitable bottle diameter |

≤80mm |

|

Conveyor height |

About 900mm |

|

Machine size |

About 3050*480*1330mm |

|

Machine weight |

About 86kg |

|

Package size |

About 1905*610*1720mm |

|

Package weight |

About 143kg |

Details

Equipped with PLC control panel,it is easy to set working parameters and control machine to run. The language of panel can be customized as your need.

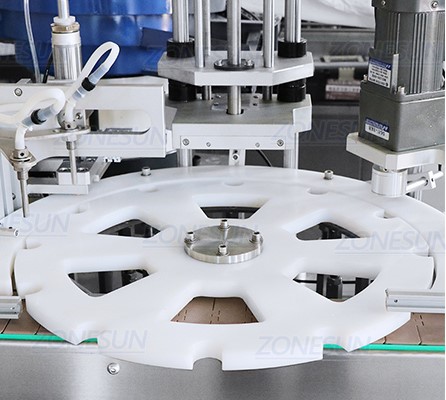

The rotary plate is designed for conveying bottles, preventing them from falling down. It can be customized according to your bottles.

With magnetic pumps,it has high filling accuracy, which suits for filling essential oil,toner. Filling speed of two filling heads can be controlled separately. The working height of filling heads can be adjusted as needed.

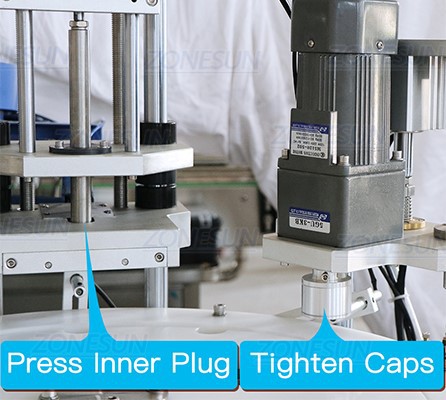

This machine can press inner plugs and cap bottles at the same time, improving efficiency. Size of capping head and pressing component can be customized according to your products.

Suitable for different shapes of bottles the label feeding mechanism can automatically work once the system detect bottles. This machine is suitable for 30mm-280mm height bottles, and we can customize the machine according to your needs.

The pipe is used to exhaust waste steam and ensures the shrinking quality. The heating tunnel is made of high quality materials, it can ensures the film can be shrunk equably.

You Might Also Like

Send Inquiry