Automatic Lipstick Filling Machine

-Feature

[Preheating Machine] It is designed for heating the lipstick residue in the mould,avoiding lipstick layering and ensuring production quality. Heating temperature can be adjusted as needed.

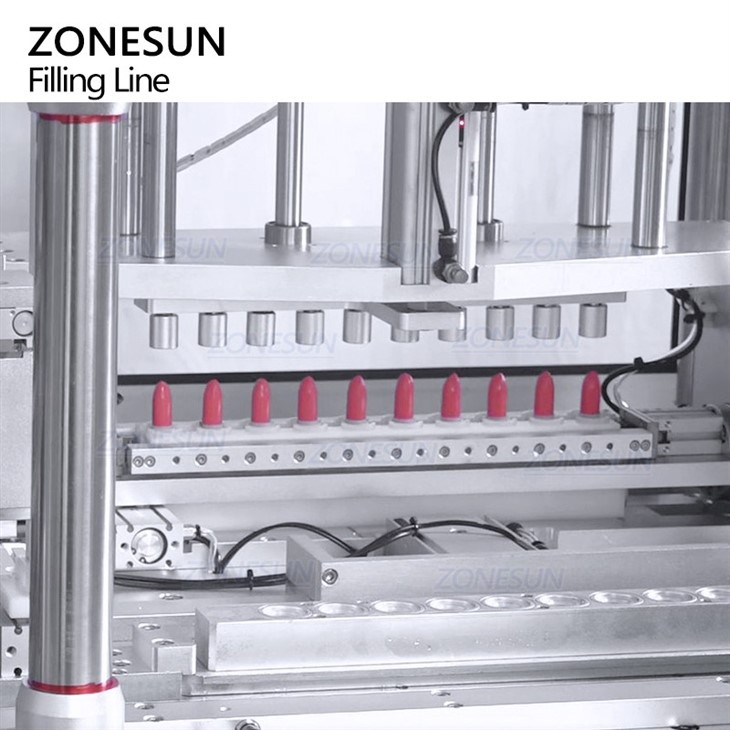

[Filling Machine] The hopper is with mixing and stirring functions, which can make filling smoothly. The filling nozzles can also keep heated during production. Quantity and filling range of the machine can be customized to meet your production need.

[Freezing Tunnel] This machine is used for cooling down lipsticks after filling process, improving production quality.

[Demoulding Machine] It can put tubes onto lipsticks and demould them, saving labor cost and improving efficiency. It can be customized as your need.

[PLC Control] The machines are designed with PLC operation panel, enabling it to control and debug the machines easily. The language of panel can be customized.

Hot Tags: automatic lipstick filling machine, China automatic lipstick filling machine manufacturers, suppliers, factory, Explosion Proof Filling Capping Labeling Machine, edible oil filling line, walnut filling machine, powder sachet filling machine, powder packing line, flour packing machine

|

Machine Model |

ZS-LPL01 |

|

Voltage |

380V 3 Phase |

|

Total Power |

About 9.8kW |

|

Production Capacity |

About 1800pcs/h |

|

Silicone Mold Size |

390*30*52mm(10-hole) |

|

Heating Tube |

2000W*2 |

|

Power of Freezing Tunnel |

3000W |

|

Power of Demoulding Machine |

850W |

|

Customization |

Available |

|

Size of Filling Line |

About 5700*1100*1980mm(L*W*H) |

Details

Equipped with PLC control panel, it is more convenient to set and adjust technical parameters. The language of panel can be customized as your need.

This machine is designed for preheating lipstick molds before filling, which can ensure production quality.

The filling nozzles can keep heated during production, which can ensure smooth filling. Quantity of nozzles can be customized.

This component is designed for putting tubes onto lipsticks and demoulding them, saving labor cost and improving efficiency. It can be customized according to your need.

The two belts are used for screwing lipstick tubes. Running speed and width of two belts can be adjusted as production need.

The automatic lipstick filling machine is a high-speed and efficient machine used for making lipsticks. The working process of the machine starts with the feeding of empty lipstick tubes into the machine's conveyor. The conveyor then transfers the tubes to the filling section, where the lipstick is accurately dispensed into the tubes using the volumetric filling method.

The machine is equipped with a vibratory feeder to regulate the flow of lipstick into the filling section. Once the tubes are filled, they move to the capping section. The automatic capping machine then accurately caps the tubes and transfers them to the labeling section.

This machine is perfect for cosmetic companies that require high-speed and consistent filling of lipsticks. The automatic lipstick filling machine ensures that the manufacturing process is efficient and of high quality.

You Might Also Like

Send Inquiry